The Power of PO Management, improving Origin Management

In shipping and logistics, the line between smooth, cost-saving operations and expensive problems often comes down to one thing, visibility. When we see purchase orders (POs) early, many weeks before booking details are final, we are not reacting, we are preparing. We can lock in space, plan schedules, and get resources in place long before the cargo is even packed.

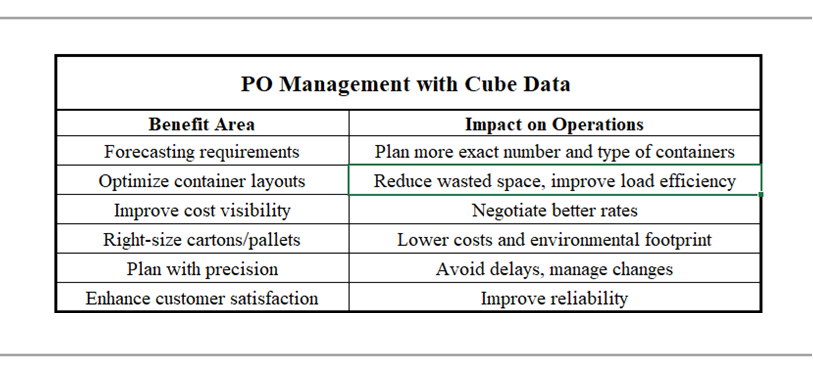

PO management takes an order management system and turns it into a true planning tool. And when we add accurate dimensions and cube data, the total volume of goods, we go from knowing just the “when” to also knowing the “how much space” exactly. That’s when we can secure the right mix of containers, plan consolidated shipments, and avoid last-minute changes that cost us time and money.

Cube is more than just a number; it’s the key to container planning. It tells us exactly how much room we’ll need, whether that means standard, high-cube, or specialized equipment. With it, we can load smarter, reduce wasted space, and cut costs. It’s also a way to lower our environmental impact by making every container count.

When we have PO data and cube together early, planning becomes precise. We can design efficient container layouts, negotiate better rates, and find consolidation opportunities we might otherwise miss. That means fewer delays, better delivery performance, and happier customers.

The real value isn’t just in the savings. it’s in the control it gives us. With this data, we see the whole shipping puzzle: timelines, space needs, costs, and chances to combine loads. We’re making decisions on our terms, not scrambling to adjust at the last minute.

Global logistics isn’t getting any simpler. We need every tool and every bit of advance notice we can get. PO management paired with cube data isn’t just best practice, it’s a competitive advantage. With the right information at the right time, we can forecast with confidence, execute with precision, and deliver the results our customers count on.