Learn how to navigate uncertainty in the supply chain with these key observations and tips for mid-September.

Navigating Labor Uncertainty: Key Updates for Supply Chain Planning Amid Potential Port Strikes

The International Longshoremen's Association (ILA) and the United States Maritime Alliance (USMX) have yet to agree on a new contract, and talks at the national level have stalled. The ILA wants local agreements settled first, while USMX wants both national and local contracts negotiated together. With the current contract expiring on October 1, the ILA is threatening to strike—a move rarely seen in recent history.

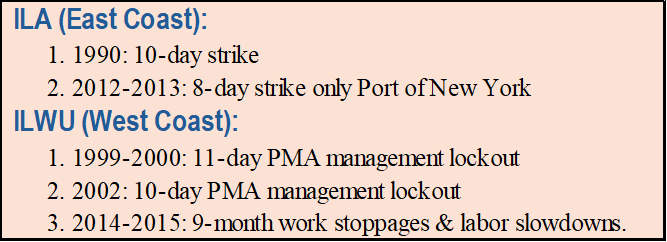

In the past, the ILA and ILWU (International Longshore and Warehouse Union) continued to work without a contract while negotiations were ongoing. In 2022, the ILWU signed a new contract 23 days after the previous one expired. In 2014, they worked without a contract after it expired on June 30 and did not strike until nine months later when a new deal was reached.

During that dispute, longshoremen used strong tactics like slowdowns, temporary walkouts, and media campaigns to put pressure on management. The 2014-2015 conflict severely disrupted West Coast ports for months, with congestion lasting another six months after the new contract was signed. Despite all this, they didn’t fully walk off the job.

These past labor disputes have severely impacted ports and the flow of goods:

What's at Stake?

The U.S. economy could be impacted, but for importers and exporters, the main concern is the effect on their businesses, with delays and increased costs. About half of the container imports and many exports pass through East Coast and Gulf ports, which handle trade with Asia, Europe, and Latin America. In contrast, West Coast ports focus more on trade with Asia.

How bad could it get?

A strike or lockout would shut down ports entirely, meaning no cargo could move in or out. The ILA could strike at some ports while keeping others open, or they could slow operations to a crawl. USMX could respond by locking the gates, but without a contract, their legal options are limited. Either way, port operations would stop.

If a strike or lockout happens, any import containers already at the port will be stuck until the gates reopen. Ships at sea may have to wait until work resumes, which could take at least a couple of weeks. Historically, strikes or lockouts last about 10 days, but the impact on port congestion can last for months.

Rerouting Options

If your shipment hasn’t left its origin yet, you could consider rerouting it to the West Coast or Canada, but others will likely do the same, causing capacity to fill up quickly. You could also look into alternative East Coast ports like Charleston, Wilmington, Norfolk, or Baltimore. These ports might help spread out the risk of congestion. Charleston, for example, is close to Savanaha to the south and Wilmington NC to the north. Norfolk or Baltimore might be alternatives to New York. Philadelphia is an alternative for Europe or Latin American shipments.No carrier serves every port, but most serve multiple, so you have options. Each choice comes with its own costs in terms of time, money and risk.

If you tend to use only one or two main ports on the East Coast, you might find spreading out the risk will free up your congestion impact. No carrier serves all these ports, but each serves several, so you do have choices.

Handling Port Congestion

Even when a strike or slowdown ends, congestion can take months to clear up. Once the ports reopen, make sure you know your priorities and have a plan. What containers and products do you need to expedite, or to move first? Can you afford to delay until later? Your logistics providers need to be included in your planning so they can perform for you. You should be consulting your best logistics partners for their recommendations or solutions.

For all of this, you need good data on what is in each container and the current or coming priorities for your business. Here’s what you need:

1. Shipper and Consignee Information

• Shipper and Consignee notification parties

2. Commercial Terms

• Incoterms and freight payment terms

3. Shipment Scheduling

• Booking & Salling dates, Carrier information, Bill of Lading details, Shipping Instructions, Tracking information, Updated Estimated Time of Arrival (ETA)

4. Cargo Details

• Container contents (by commodity or SKU), Weight, Pieces, Hazardous materials (if applicable)

5. Logistics Partners

• Broker name and contact, Dray carrier name and contact, Destination contact information

6. Delivery Information

• Arrival port, Final destination, Customer name and contact, Special delivery instructions

Having access to this data enables you to prioritize shipments based on urgency and importance!

| # | Task |

|---|---|

| 1 | Make informed decisions on rerouting or expedited shipping |

| 2 | Improve cargo clearance and delivery processes |

| 3 | Crossdock via truck, Truckload or LTL as necessary |

| 4 | Enhance supply chain visibility and transparency |

| 5 | Improve communication with logistics partners and customers |

By using accurate and timely data, you can mitigate the delays you are working through and ensure smoother shipment management.

Other Considerations

Know What's Inside: If you know what you have inside a container (item-level is best), you can match that up with your needs.

Communicate Priorities: Share your priority list with your team and logistics providers to keep them updated. You need these inside and outside partners to have advance notice of your plans and what is coming.

Explore Crossdock Options: Knowing this gives you many flexibility and expedite options, but you need good logistics support and planning.

Local Warehouses: These can offer temporary storage or cross docking and tend to be the most flexible and willing partners. If you need to set some up, push your logistics providers to make recommendations.

Evaluate Your Providers: Good providers should not only advise you but also help execute your plan. You may find you need to make some changes!

Setting Yourself up for Success

WOWL is a logistics solution provider that connects with your carriers, forwarders, brokers, and dray carriers to harness their data and communicate your instructions. WOWL can also include other providers as possible solutions for you. WOWL uses an advanced planning platform with AI capabilities and has experts who specialize in finding solutions and resolving issues.

As a logistics professional, you need to have choices and options to decide the best path forward. That is why it's important to have logistics experts available to you, and trusted providers you can depend on who are willing to build solutions for you!

WOWL can manage booking and origin process for rerouting your orders with your carriers or forwarders on a best alternative that can be executed, and they can then follow that shipment through to final delivery. They do not just provide visibility—they interact with your providers all the way from booking, shipping, and sailing to final delivery. Then they can even make sure an empty container gets returned on time.

In tough times, like the potential strike or lockout, look to WOWL for trusted solutions.